Laboratory

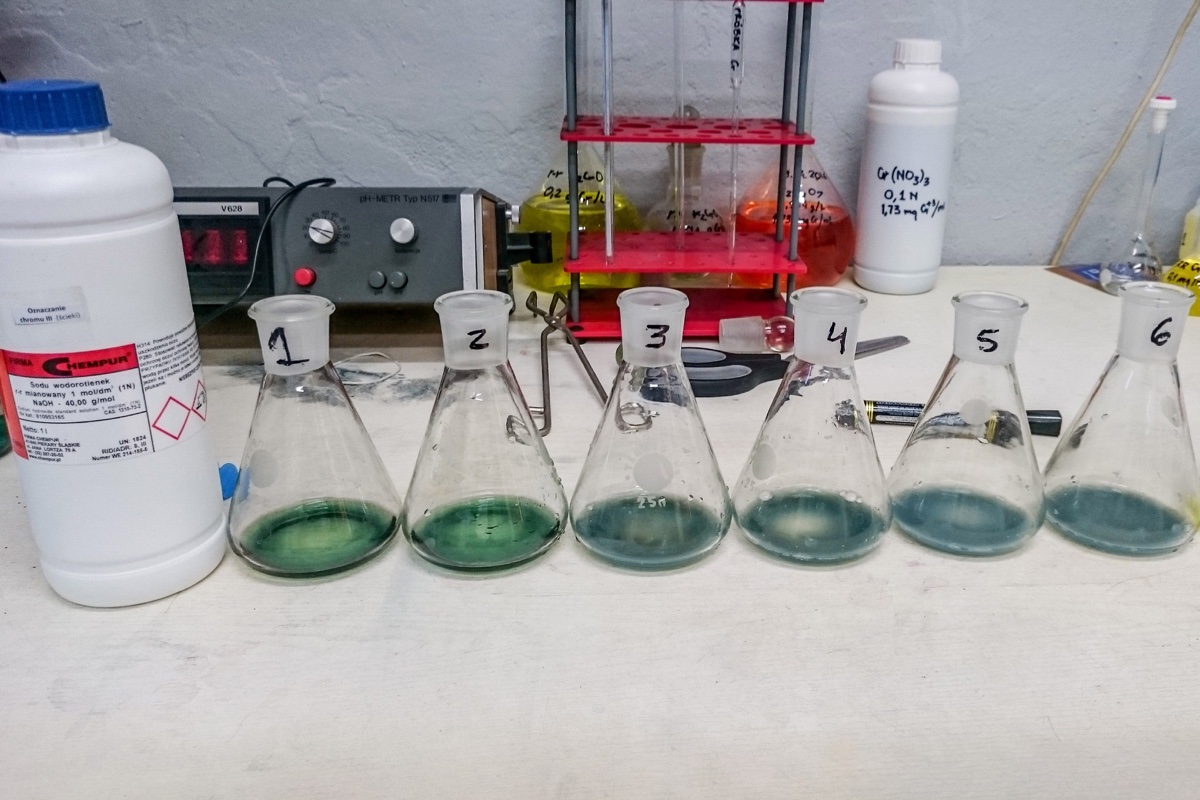

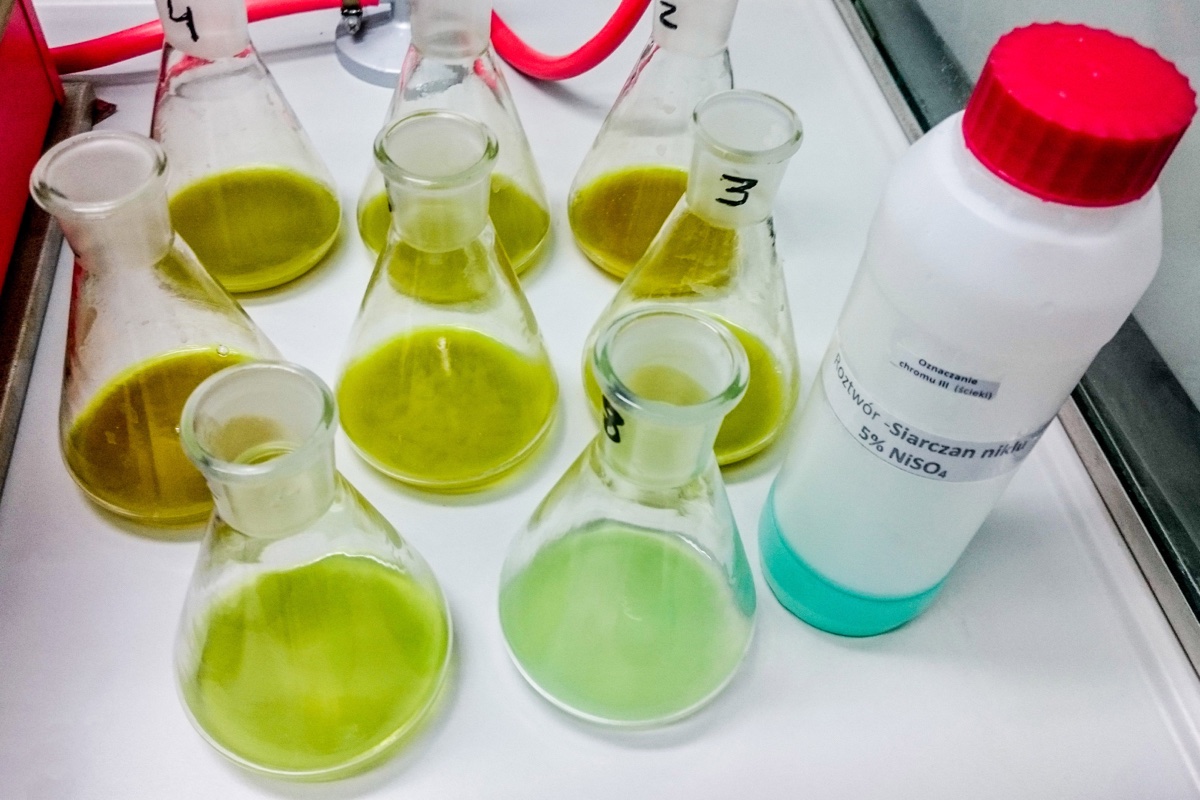

We have a laboratory at our customers’ disposal where we can perform technological tests as well as most of the tests

physico-mechanical and basic chemical tests on leather.

Our company employs a team of specialists who are happy to provide comprehensive assistance in turning leather into attractive and fashionable ranges.

Management, advice and technical service are provided by tanning technologists with many years of professional experience. Our staff will solve problems concerning the leathers’ leaching and finishing at every stage of production, in accordance with the most modern global trends and using the best resources.

STAHL products meet all the environmental requirements of the European Union.

In our laboratory we carry out wet workshop, tanning, oiling, dyeing and leather finishing tests.

In addition, we carry out the following physical and chemical tests on leather:

- Determination of water resistance of flexible leather (penetrometer)

- Water vapour absorption, water vapour ratio

- Adhesion of finish

- Thickness

- Colour fastness to cycles to-and-fro rubbing, dry, wet

- Colour fastness to artificial perspiration

- Colour fastness rotative rub fastness and to-and-fro rubbing, dry, wet

- Determination of wet or dry flex resistance and of leather sub-zero temperatures

- Determination of pH and difference figure of an aqueous leather extract

- Water vapour permeability

- Determination of tear load. Double edge tear

- Determination of tear load. Single edge tear

- Resistance to damage on lasting

- Determination of tensile strength and maximum elongation

- Chromium (III) content by iodometric method

- Determination of matter soluble in dichloromethane

WE LOOK FORWARD TO WORKING TOGETHER

Comprehensive information and advice is available on the following telephone numbers:

Tanning

Sylwia Chrząszcz

t: +48 503091213

e: sylwia.chrzaszcz@martpol.com.pl

Tomasz Kiełbasa

t: +48 502255463

e: tomasz.kielbasa@martpol.com.pl

Krzysztof Kaczmarek

t: +48 501 090 285

e: krzysztof.kaczmarek@martpol.com.pl

Finishing

Andrzej Mendrycki

t: +48 509 708 879

e: andrzej.mendrycki@stahl.com

Fur farming

Michał Ludwicki

t: +48 501371690

e: michal.ludwicki@martpol.com.pl